Controlling your gap technique between workpieces is an essential part of achieving high-quality, consistent welds. Without gap control, you risk improper penetration, undercutting, or excess heat input. Whether you’re fabricating plates or using a pipe welding machine, mastering this important skill will result in stronger joints.

1. Measure and Mark the Gap

Every fraction of an inch matters when working with tight tolerances. Always start by measuring and marking the required gap based on your welding procedure. Use gap gauges, calipers, or templates to maintain consistent spacing. Confirm the gap is uniform across the entire joint, especially when welding pipes or thin materials. An uneven gap can lead to uneven welding beads.

2. Use Fit-Up Tools

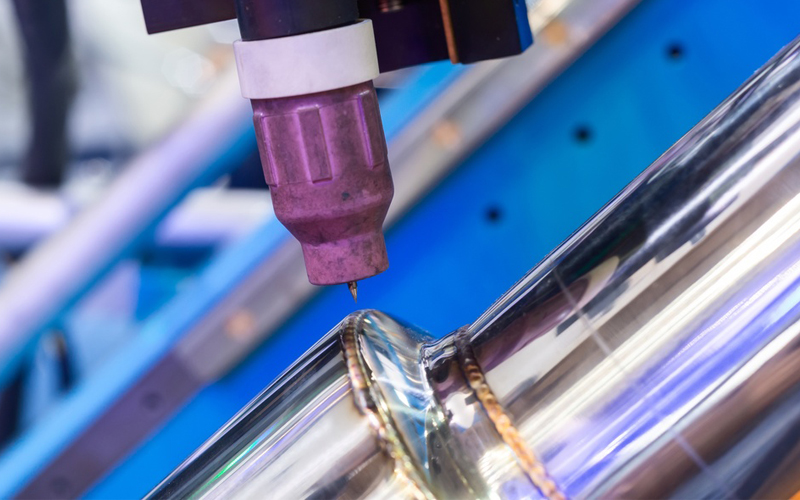

Fit-up tools, such as clamps, tack welds, or pipe alignment tools, hold materials in place while welding. Tack welds can temporarily secure the parts and prevent the gap from shifting during welding.

Specific tools, like InterPurge Pipe Alignment Clamps, pair exceptionally well with a pipe welding machine when aligning and clamping pipes. They are available in different sizes and produce exact results with minimal distortions. These clamps feature alignment balls to reduce marring and large threads for quick and easy adjustments.

3. Account for Material Expansion

Adjust your gap when working with materials that expand or contract during heat cycles. For instance, different temperatures during preheating or welding can expand metals and narrow the original gap. Maintain even spacing throughout the weld pass by leaving room for these changes in your setup.

4. Incorporate Spacers or Backing Rings

Spacers or backing rings are useful for producing consistent gaps across large sections or challenging joint configurations. They guide and support materials during welding, minimizing warping or shifting.

Backing rings provide further support by stabilizing the materials and preventing them from similar effects. Spacers provide uniformity in gaps across similar joints in repetitive processes or heavy-duty applications.

5. Inspect and Adjust as You Go

Don’t rely solely on your measurements at the start. Continuously inspect the gap, and adjust if needed. This is especially necessary with long welds, where heat can affect the alignment. Use wedges or alignment pins to tweak the gap as you progress, and make small adjustments during welding to avoid rework later.

If you’re looking for reliable tools to improve your gap control, SEC Industrial offers a selection of equipment, including tools that work with a pipe welding machine.

Perfect Your Gap Control Today

Consistent welding starts with preparation, and gap control is a fundamental technique in this process. By following these approaches, you’ll improve weld consistency, reduce defects, and save time on repairs or rework. For high-quality welding tools and support, contact us at SEC Industrial.